VB-CPS recycling unit

VB-CPS (Centruder® Purification System) is a recycling unit based on the waste decontamination during melt phase using the Centruder®, a device (patent pending) based on the combination of melt centrifugation and vacuum.

- Process is ideal for the treatment of any kind of waste.

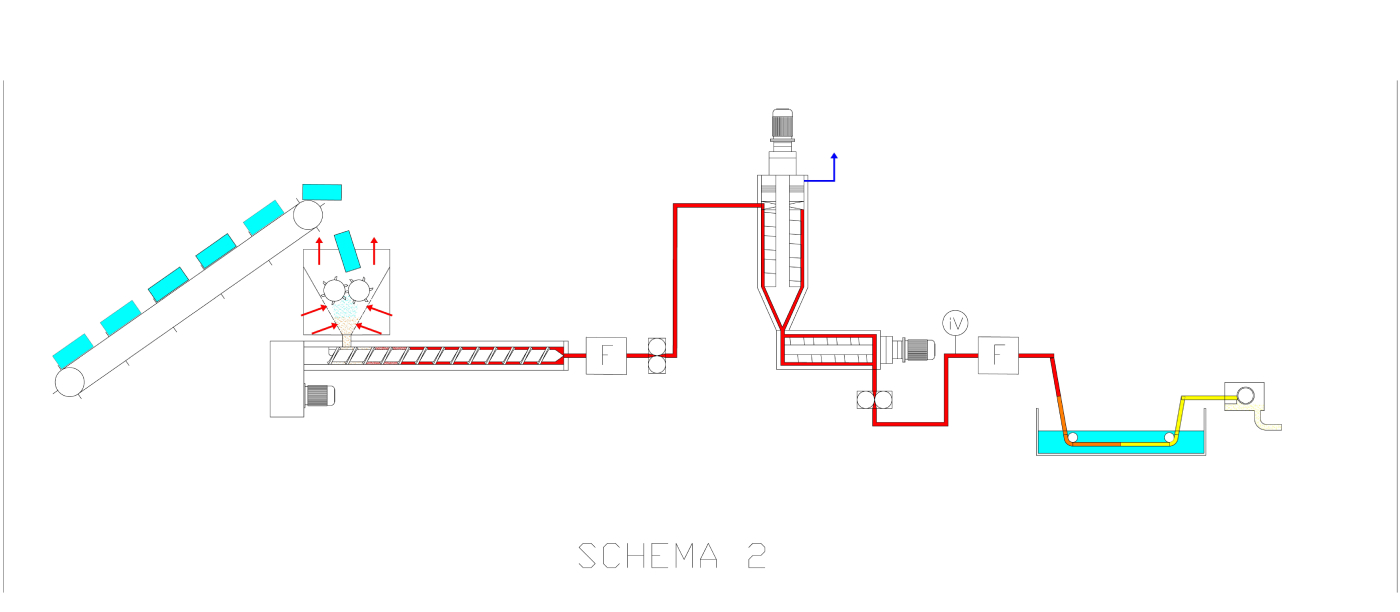

- Waste is grinded into a shredder suitable to process waste in different forms (fibres, fabrics, non woven, etc.)

- Waste is loaded in a single screw extruder, where it is melted and pushed into the Centruder®

- Inside the Centruder® a combination of melt centrifugation, temperature and vacuum allows the deconta mination of the melt from all volatiles without degradation of the product.

- If required, the system can increases the viscosity on the melt phase by introducing the adequate combina tion of temperature, vacuum and time.

- After the decontamination treatment, the melt feeds a booster pump, where the polymer is pushed into the mechanical continuous filtration. Once filtered the melt enters in the pelletizing unit, model to be selected according to the type of material.

Highlights:

- Efficient decontamination in melt phase

- Suitable for internal waste recycling

- Suitable to increase product viscosity

- Suitable for PET, PA, PP, PE in form of granules or flakes

- Capacity from 100 to 800 kg/h

- High quality pellets

- Flexible product change

- Easy maintenance

- Low energy cost

- User friendly HMI