VB-IPS recycling unit

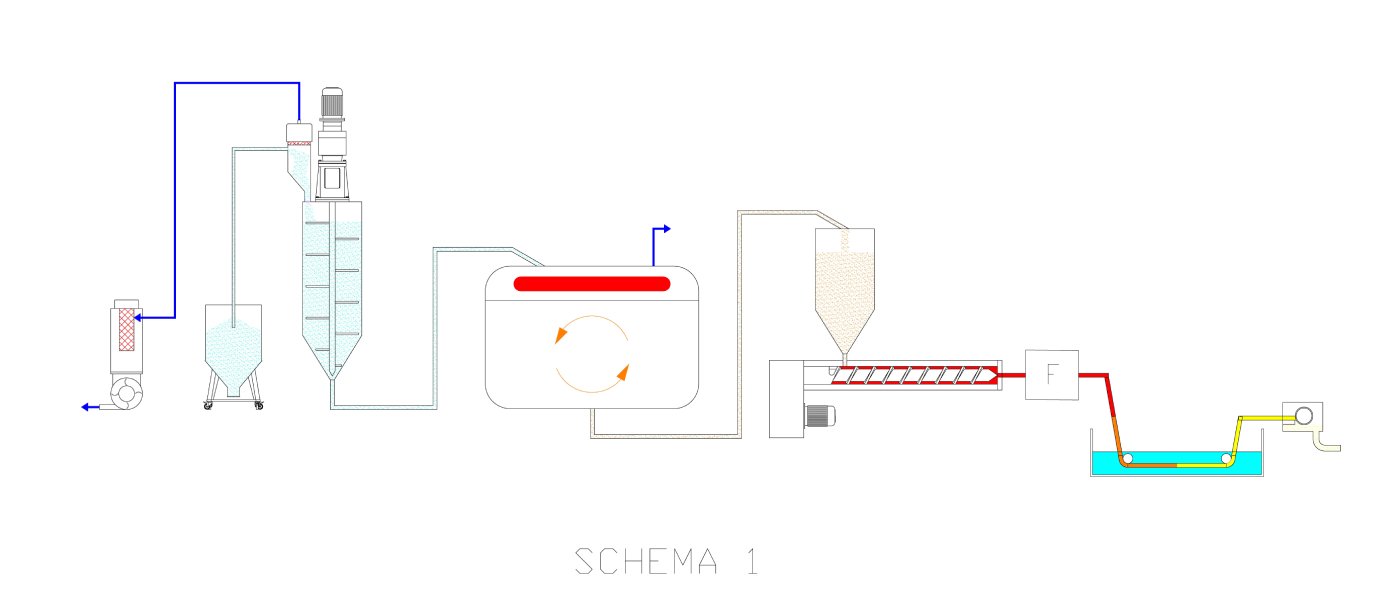

VB-IPS (Infrared Purification System) is a recycling unit based on the waste decontamination in solid state using a combination of infrared and vacuum

- Process is ideal for the treatment of waste in the shape of flakes or granule.

- Granules/flakes are pneumatically loaded in the infrared unit, where they are efficiently heated using infrared, while the granules/flakes are mixed with a special recirculation system

- Combination of temperature and vacuum allows the decontamination of the granules/flakes from all volatiles without degradation of the product.

- Homogenization of the product by special recirculation system

- If required, the system can increase the waste viscosity compensating its viscosity loss by introducing the adequate combination of temperature, vacuum and time,

- After the decontamination treatment, the granules/flakes are feeding a single screw extruder, where the polymer is melted and pushed into the mechanical continuous filtration. Once filtered the melt enters in the pelletizing unit, model to be selected according to the type of material.

Highlights:

- Efficient decontamination in solid state

- Suitable for internal waste recycling

- Suitable to increase product viscosity

- Suitable for PET, PA, PP, PE in form of granules or flakes

- Capacity from 100 to 800 kg/h

- Viscosity homogenization by special recirculation system

- High quality pellets

- Flexible product change

- Easy maintenance

- Low energy cost

- User friendly HMI