VB-MAST

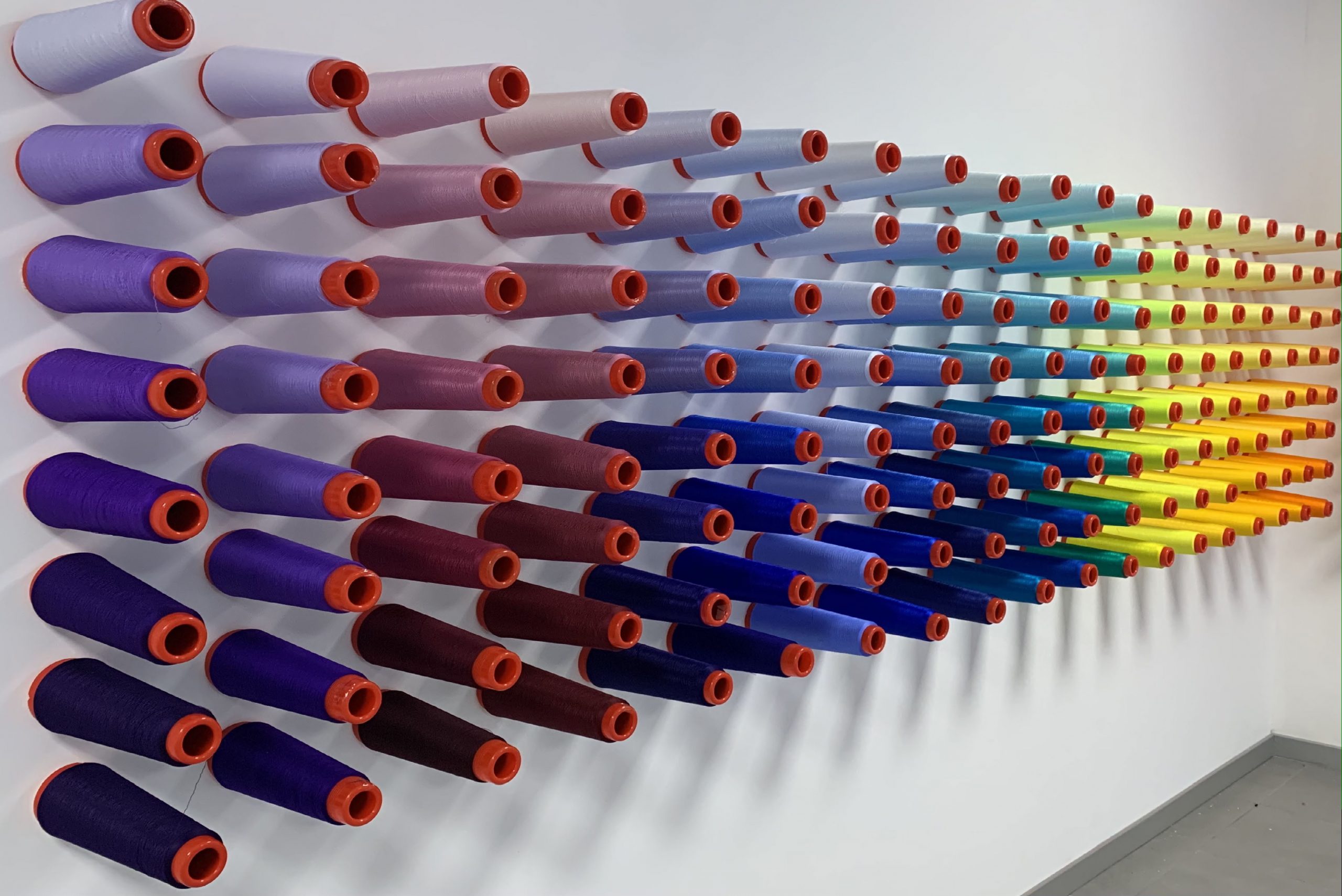

Dope dyed (solution dyed) technology for POLYESTER – POLYAMIDE – POLYPROPILENE

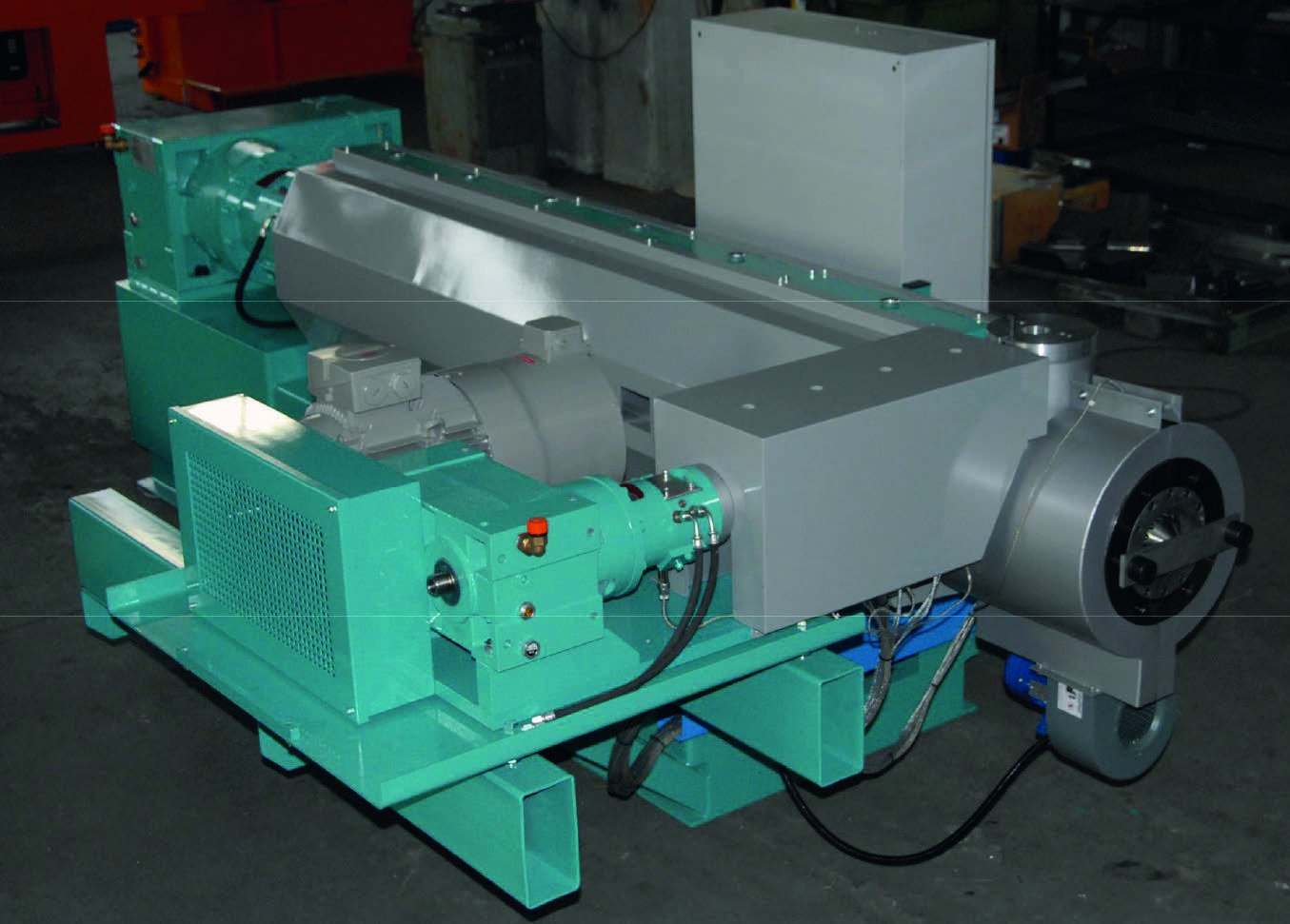

VB-MAST side-extruder concept is the state-of the art solution to produce high quality dope dyed (solution dyed) yarn.

Dope dyed yarn spinning is year after year becoming a key factor to reduce the environmental impact of the package dyed and piece dyed processes.

Producing colour yarn with VB-MAST technology eliminates all water pollution and discharge of harmful waste.

Highlights:

- VB-MAST is based on a dedicated design of dynamic mixer developed to allow a very uniform mixing of the white melt stream with the coloured melt, without colour degradation.

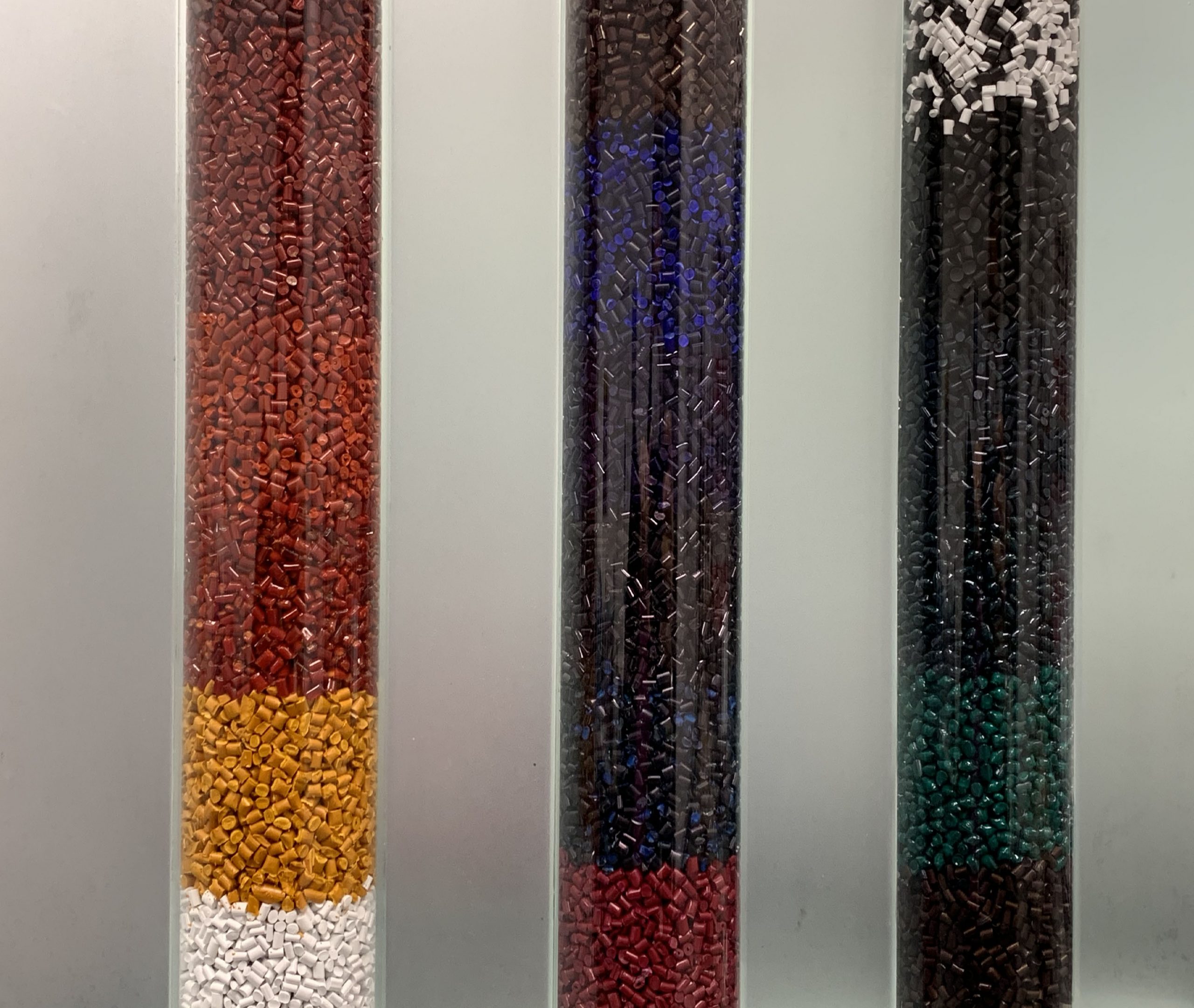

- Accurate process control on pressure, temperature and mixer revolution speed allows to repeat the colour time after time. It is possible to adjust shade deviations inducted by variation in the raw material.

- Using dedicated side extruder to melt the master batch, the main extruder is never polluted.

- The Melt injection unit is easy dismountable for fast cleaning.

- The colour melt dosing is performed by a metering pump for the most effective and precise dosing.